Waste effluent is an inevitable outcome of any industrial chemical cleaning process. Responsible service providers will often address this problem by either developing a procedure to minimize waste production, creating conditions for efficient disposal, or both. Creating conditions for efficient disposal first requires separating the waste into its distinct phases including oil and aqueous phases over solid sediment. The second stage can be detailed and complex but typically entails treatment and processing of each phase to ensure an environmentally responsible fate.

West Penetone seeks to support such responsible management of waste effluent through the following efforts:

1. Waste minimization – developing chemical cleaning procedures that minimize the production of disposable effluent.

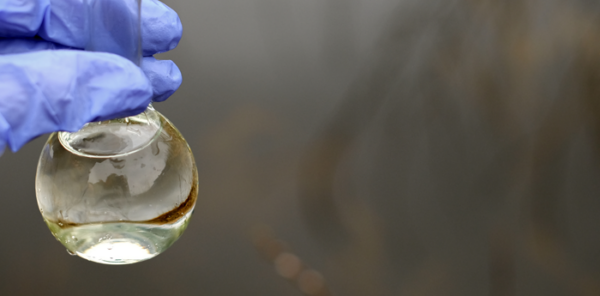

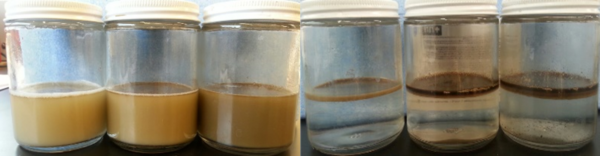

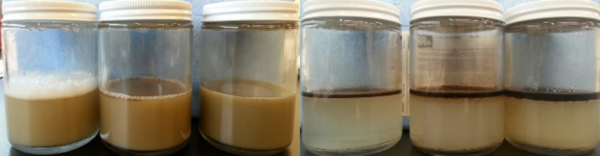

2. Waste holding treatment programs – delivering effective chemical treatment programs to support separation of waste effluent during holding. Examples of such support include emulsion breaking programs for Citrikleen and ROC product effluent, as shown in the figures below:

Figure 1 – 2% v/v CITRIKLEEN samples before and after breaking emulsions containing 2%, 5% and 10% v/v hydrocarbon content respectively.

Figure 2 – 2% v/v ROC 60VP samples before and after breaking emulsions containing 2%, 5% and 10% v/v hydrocarbon content respectively. The aqueous phases later clarified with demulsifier.

3. Ingredient transparency – supporting treatment processes by fully disclosing all ingredients on safety data sheets and providing free and open access to all product documents on the West Penetone website.

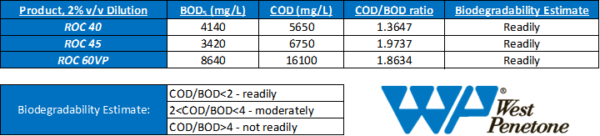

4. Throughput support – providing detailed information on product properties to determine fate of ingredients during treatment and processing. This includes providing biodegradability estimates as shown for the ROC products below:

5. Eco Logo approved product line – where holding, treatment, and processing of waste effluent is not feasible, providing an Eco Logo approved product segment to ensure responsible product fate and stewardship.

The more general efforts noted above have been demonstrated in a variety of ways not limited to detailed throughput breakdowns including phase solubility or boiling point and decomposition temperature of each ingredient, ensuring optimum product volume recommendations for the project at hand, international regulatory registration of products such as ROC 40-E3 through CEFAS and the OCNS, and more.

Of course, identifying optimum product volumes and developing a chemical cleaning procedure that minimizes waste effluent production requires knowing the best product to target the fouling issue at hand. If in doubt, be sure to speak to your local West Penetone representative for advice.